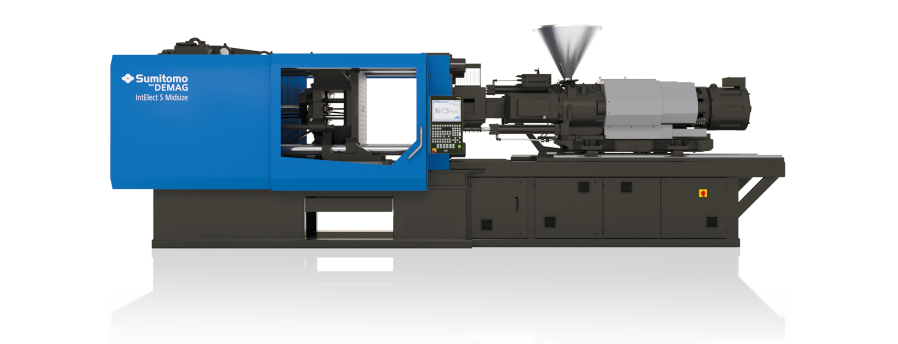

Highlights of the all-electric IntElect series

- Precise and dynamic

Highly dynamic direct drives specifically developed for injection moulding. - Extensive mould space

Large tie bar distance adds flexibility and saves footprint. - Energy efficiency

Up to 80% more efficient compared to hydraulic machines.

Available from 500 to 5000 kN

- Incredible speed

High injection dynamic, high injection speed and fast mould movement. - Long lifetime

Motor and spindle specifically developed for high-performance applications. - Energy efficiency

Up to 50% more efficient compared to high-performance hybrid machines.

Available from 500 to 4500 kN

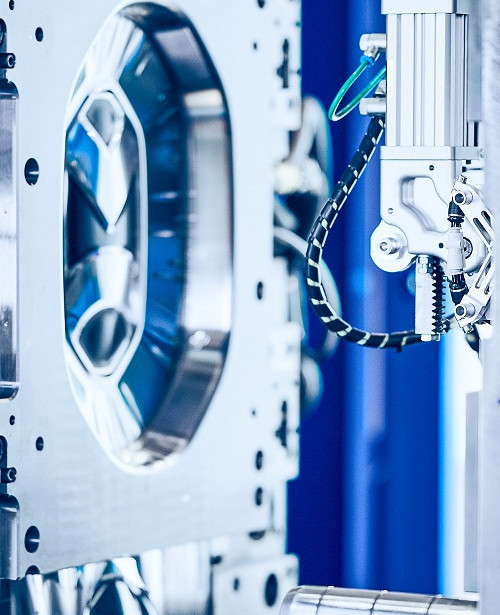

- Extensive mould space

Large tie bar distance for maximum turning diameters. - Precision

All injection axis drives are perfectly aligned for optimal moulding results. - Efficiency

Low energy consumption, shortest cycle times and parallel, dynamic movements.

NC5+

Intuitive machine control system

- Adjustable clamp force stages (special feature of the IntElect)

- Simple operation and easy familiarisation

- Clear layout of the screen pages and soft keys

- Transparent process analysis with reference cycle graphics

- Automatic production documentation

- Control and reference position for clamping unit at the touch of a button

- Automatic mould height and clamping force adjustment

- Automatic injection system for time-saving shut-down and start-up