Reduced part weight and increased mechanical properties

Physical foaming is a process used in injection moulding to produce lightweight plastic parts with stronger mechanical properties. It involves introducing a gas into the polymer melt to create small, evenly distributed bubbles throughout the material. These bubbles reduce the density of the plastic, resulting in a lighter weight part, while also improving its stiffness, strength, and thermal insulation properties. Dissolving the gas also reduces the melt viscosity, making it even easier to fill thin-walled components. This technology is widely used by the automotive, packaging, and construction sectors, where lightweight and strong plastic parts are in high demand.

- Induction of the gas into the plasticising unit

- Gas absorption and diffusion inside the thermoplastic mass

- Injection

- Pressure drop inside the the cavity initiates gas expansion and foaming

- Cooling

- Mould opening and part ejection

- Plasticising unit adapted to MuCell® technology, including special plasticizing screw

- Shut-off nozzle

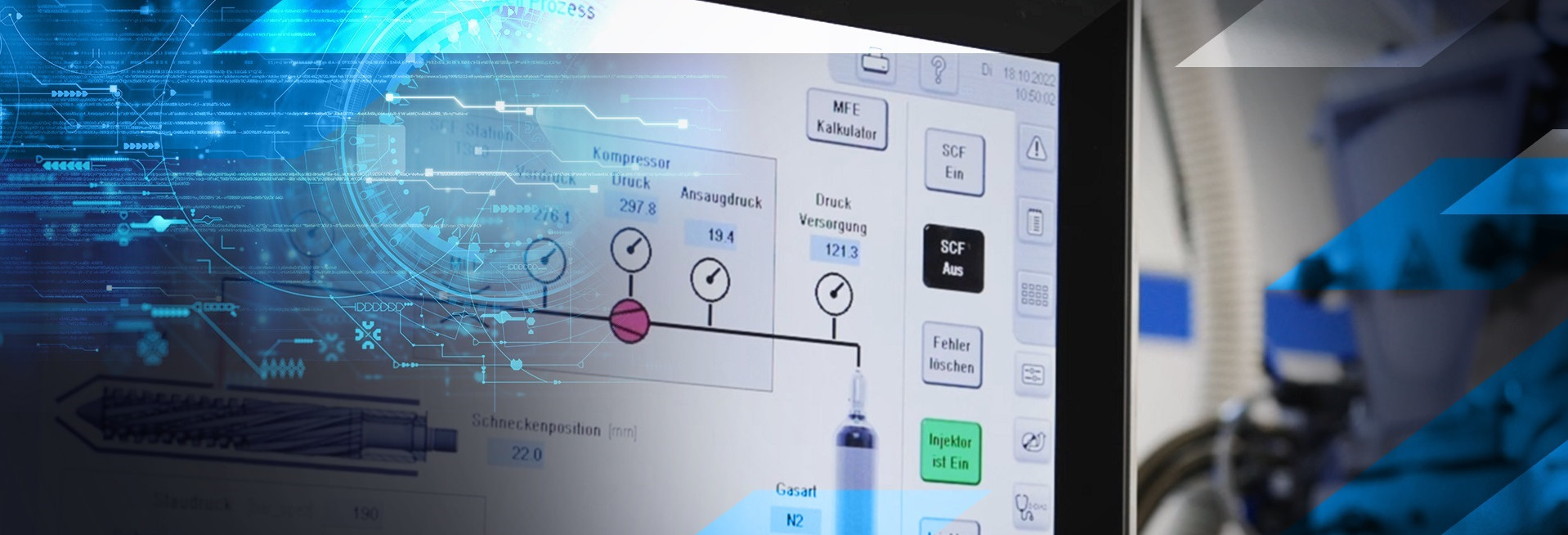

- Gas dosing unit (MuCell®)

- Gas injector (MuCell®)

- Fully-integrated peripheral devices in the machine control

- Safety setup

- Part weight reduction up to 40%, depending on the application

- Reduction of sink marks and warpage

- Reduction of the clamping force/required machine size

- Reduction of the injection pressure required to fill the mould cavity

- Energy saving through reduced cycle and cooling time

- Automotive industry (housings, covers, structural components)

- Consumer industry (housing components)

- Packaging industry (containers, lids, etc.)