Everything from a single source

One-stop automation-shop

S.A.M. (Sumitomo (SHI) Demag. Automation. Machine.) is our in-house automation portfolio covering all aspects of automation and designed specifically to support injection moulding. With our interdisciplinary, industry-experienced teams and our network of over 500 experts, we cover the entire spectrum of injection molding automation: machine technology, robotics, conveyor technology and networked control and information technology. In addition to a high-degree of standardisation, we also scope out and support customers with large-scale automation projects.

Network of over 500 experts

Our expert network covers the whole spectrum: machines, robotics, conveyors, networked control technology, etc.

From standardised to complex projects

No matter which application: We provide the right automation solution for your project.

Innovative robotics solutions

Our SAM robot portfolio offers solutions to suit any application and integrates into any production cell.

Key ready production cells for automotive, electronics and consumer goods' applications

Easy Automation

handle&place

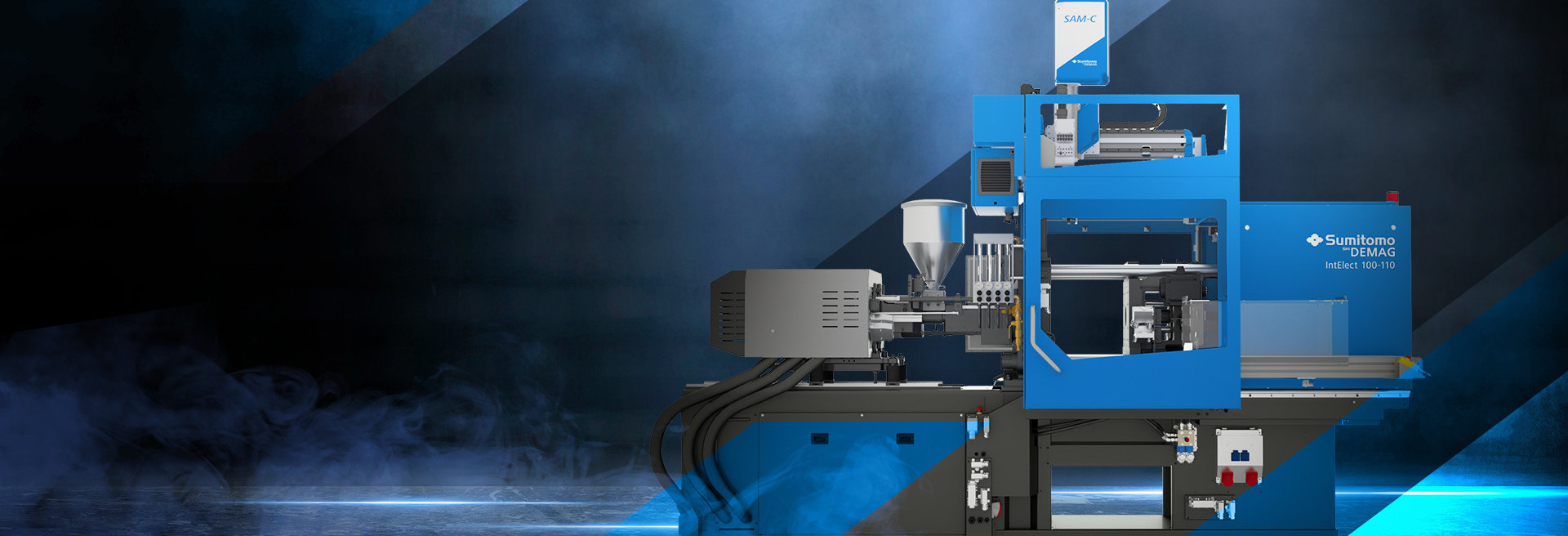

The standardised CE compliant production solution comprises:

- Injection moulding machine (Systec/IntElect)

- Fully integrated SAM-C robot

- Standardised protective housing with conveyor belt

The machine, robotics, process technology, and conveyor technology are fully-integrated into our NC5+ control software.

handle&box

The CE compliant production solution comprises:

- Injection moulding machine (Systec/IntElect)

- Fully integrated SAM-C robot

- Storage/buffer system, providing greater autonomy to reduce human labour

The machine, robotics, process technology, and conveyor technology are fully-integrated into our NC5+ control software.