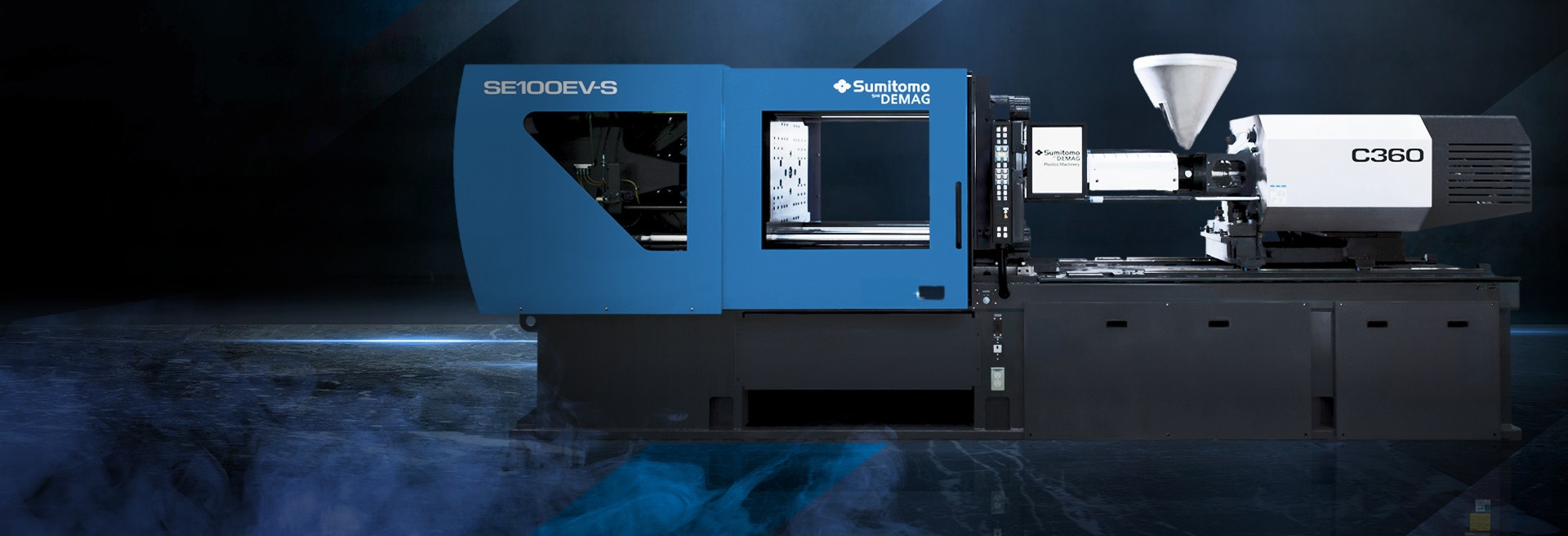

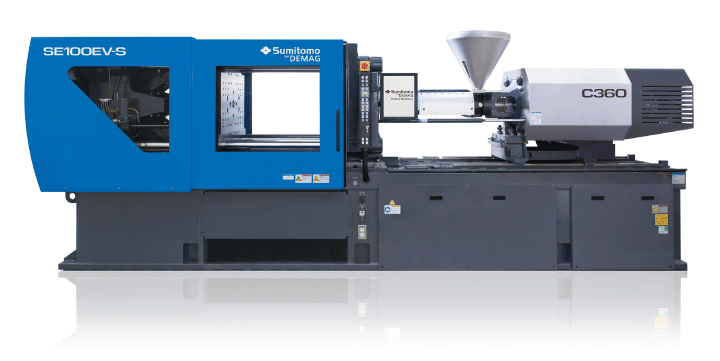

Highlights of the SE series

Thanks to the direct servo-motor drive and intelligent servo-motor control, the SE series machines meet the increasing demands of the moulders in an ideal manner. A powerful and quick-acting injection unit and an absolutely reliable, accurate and quick-acting clamping mechanism bring the SE machine range into the top class of all-electric machines.

Getting as close to zero defects, losses, and faults as possible

Zero-moulding with the SE series

Read more about Zero-moulding and the SE series on the SHI website

Read moreZero-moulding is an integration application, consisting of three elements, that achieves as close to zero defects, losses, and faults as possible.

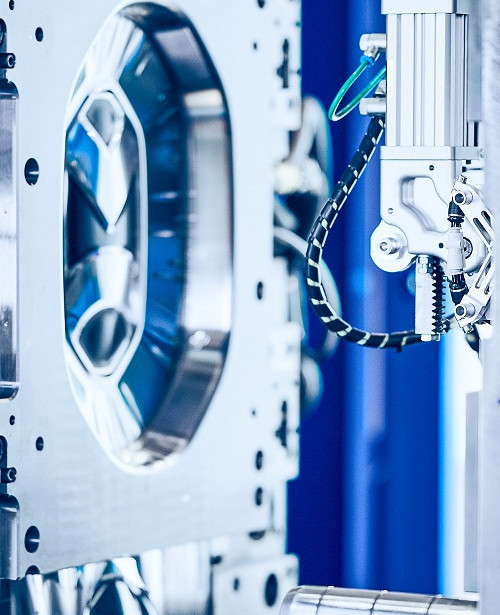

- MCM (Minimum Clamping Moulding)

Make use of the vent effect to reduce maintenance and extend mould life. - FFC (Flow Front Control)

Low pressure and smooth filling helps the discharge of gas and improves cavity balance. - SPS (Simple Process Setting)

Intuitive interface to simplify use and access to powerful features.