Clamping down on heat generation

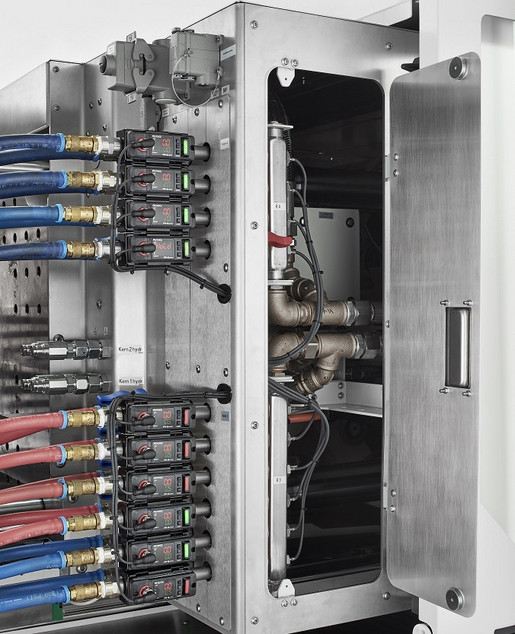

Over cluttering is not conducive to the GMP standards. Removing free-standing periphery equipment from the floor and integrating into the moulding machine cell, including hot runner controllers, cables, and even automation, eliminates another surface area and consequently additional sources of heat generation.

Integrated electric direct drives is another consideration. Providing the force transmission, one of the key processing advantages of electric drives is the ability to control the linear axis with velocities in excess of 500mm/s. With no belts spinning, the drives don’t have to work as hard.

This increased efficiency gained from direct drives means that they use considerably less energy – in the case of the IntElect between 40% and 85% less than conventional solutions.

Having this level of drive control also makes a subtle difference to clamp force. Use too much force and the machine’s energy consumption rises. Rather than diverting straight to the maximum clamp force, a medical IntElect machine, with its smaller than average injection unit, can override and select the appropriate clamp force for a particular combination of component geometry and polymer material. For high cavitation medical components, where precision is fundamental, this is a gamechanger, as the machine isn’t overworking itself, which not only generates excess heat, but can also cause premature tooling wear and tear.

Heat transference is another consideration. A portion of electrical power is used to directly heat the barrel to melt resin. Another to run the machine drive, inverters and motors, which in turn also generates heat. All of the heat generated must be dispersed either via thermal convection or – in most cases – an active cooling system.

Thermal imaging of the direct drive provides a good indicator of any inefficiencies and heat emissions. On the IntElect machines, the active air cooling (fan) is not activated until the motor reaches 55°C. If no heat emission on the drive, no additional energy is consumed.