Press

Sumitomo (SHI) Demag reports positive conclusions from K 2025 and strategically realigns its trade fair presence across Europe

Increase productivity, minimise costs: Integrated automation solutions at K 2025

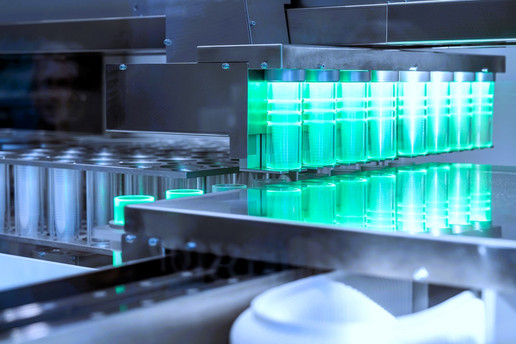

Efficient high-speed production of beverage caps

Clean toggle PAC-E powers medical excellence

Page 2 of 19