In a cycle time of just 35 seconds, the IntElect LSR package produces 12 gram Smart Caps with absolute precision. Featuring a 570 mm wide tie bar, the generous tool space is especially suitable for accommodating multi-cavity and complex tools, explains Aliyev. Highlighting that the system and corresponding LSR package perfectly match the high-precision processing requirements for this application.

Achieving outstanding process stability, the actual weight of the parts is 0.01 grams accurate. "Vacuuming and venting provide optimal tool support. The synchronised sequence of the axes is highly precise and perfectly parallel to each other. Additionally, the system is extremely efficient, characterised by very low energy consumption. While the OPC-UA interface between the moulding machine and LSR dosing systems supports interoperability to support data contextualisation,” says the expert.

LSR heavyweights join together

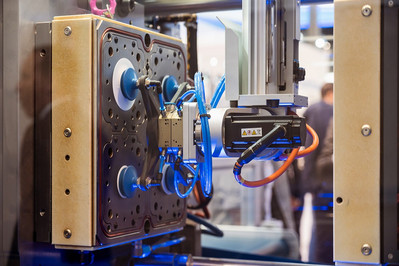

For the first time, Sumitomo (SHI) Demag exhibits with LSR tool specialist and innovator ELMET. Collaborating with the Austrian firm to design the turnkey production cell capable of producing four different LSR beverage and food can covers, ELMET’s all-electric SMARTshot E valve gate cold runner system features servo-driven nozzle needles to boost control and optimise filling behaviour.

Material is dispensed via the Smart-Mix TOP7000 Pro dosing system. Processing precision is closely monitored, with the weighing cell documenting each individual cap weight to instantly identify any moulding deviations. For traceability, the finished Smart Caps are laser marked.

“Combining the high-precision dosing system with the IntElect and the reliable processing control attained by the electric needle valve cold runner, an unprecedented accuracy of the part weight is repeatably replicated," assures Aliyev.

ELMET states that with a footprint of just 45 by 31 inches, its Smart-Mix TOP7000 Pro pump unit is capable of operating at pressures of up to 210 bar (3045 psi), yet is very compact. The result is smaller LSR volumes in the system, therefore increasing process reliability and reducing purging volume.

SAM-S robot premiere

Visitors to the LSR exhibit will also experience the global unveiling of Sumitomo (SHI) Demag’s very latest proprietary robot – the new 6-axis SAM-S12 with vertical telescopic design. SAM-S (Scara) builds upon the SAM-C (Cartesian) in-house range launched by the company in 2021, and once again redefines the firm’s customised robotics competence, based upon individual application requirements.

A 6-axis hybrid robot comprising Scara mechanics and linear robots, the SAM-S is available in two payloads (12kg and 25kg). This series has been designed for injection moulding machines with clamping force ranges from 130 tons to 1,000. The basic robot in the SAM-S series has five servo axes. The sixth axis is optional.

Fully integrated into the LSR IntElect cell, another special feature of SAM-S is the use of Sumitomo robot gearboxes. “Their high precision is especially beneficial for hybrid kinematics," reports Aliyev. Additionally, the SAM-S applies the company‘s in-house drive technology, including servo motors and precision gearboxes. Further robotic kinematics and functional elements will be added to the SAM robotics portfolio in the future.

Seamlessly automated processes

The SAM-S12 (12kg payload) being exhibited covers a large work envelope. Its special 6-axis kinematics enables the robot to perform multiple processes, including part removal, separation, testing, marking and sorting, notes Aliyev.

Additionally, the introduction of SAMControl allows for easy integration of peripheral devices. New to K 2022, the SAMControl interface utilises the same injection moulding machine and robotics hardware and software, meaning everything, even remote maintenance via ‘myConnect’ and additional processing components, can be synced and controlled simultaneously, via one control unit.

Exemplifying these benefits of total integration is the SAMSign laser marking system. Using state-of-the-art laser technology, high-quality ‘cold’ markings are applied. "The overall system has a compact footprint with good accessibility and easy robot operation," reassures Aliyev.

After removal, the parts are transferred to the weighing cell supplied by Mettler Toledo (USA). Here, each individual part is weighed and stored in a database. To assist quality managers visualise processing accuracy, data is graphically displayed. For batch traceability, all silicone parts are then marked by laser. LTL (Italy) supplied the laser system.

Parts are then deposited on an MTF conveyor belt. The liquid silicone is supplied by Shin-Etsu Silicones (Japan), and the temperature control unit comes from Regloplas (Switzerland).