Although modest, progress within the automotive sector is slowly returning to more stable levels. With components engineered for Internal Combustion Engines (ICE) increasingly being superseded by batteries, electrification components, software and digitisation, visitors to Fakuma 2024 can discover what the Net Zero road ahead looks like for OEMs and suppliers of mobility components. Including how best to embrace the latest technological transformations and reposition themselves in this ever-evolving landscape.

“Where there is growth coupled with strong competence there remain opportunities. Those that adapt to the future transformation challenges in the value chain will emerge stronger,” highlights Rustam Aliyev, the company’s LSR expert and Business Development Director of Automotive & Electronics. Aliyev cites the shift towards mass EV production as a prime opportunity for the automotive supply chain to review their vertical integration layouts and processes and grow their competencies in multi-moulding and LSR.

Flawless production future-proofed

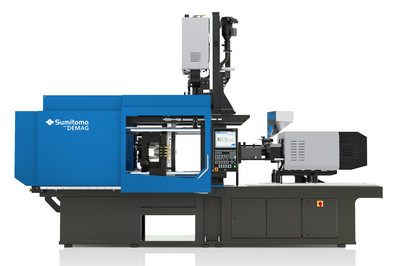

On the main booth (B1-1105), Sumitomo (SHI) Demag will present a compact all-electric multi-moulding solution. “In the automotive sector especially, multi-moulding was historically performed on hydraulic machines. As well as being heavy on energy consumption, accommodating the tool as well as the turntable typically requires a larger footprint,” notes Aliyev. By increasing the mould space on the IntElect Multi, the Sumitomo (SHI) Demag team has succeeded in engineering an energy-efficient, dynamic, multi-component machine that is even more compact.

As experts in partially chrome-plated plastic moulded components, longstanding customer BIA Kunststoff- und Galvanotechnik supplies the 2 cavity, 2 component tool. The 2K injection moulding process sequentially injects the ABS surface before back injecting with a PC shoring component to create a console button. The galvanising phase performed by BIA would then involve electro plating the component, for example with back-lit symbols, before installing in the central control unit of premium passenger vehicles.

The IntElect’s servo technology and parallel function is critical for the smooth and fast rotation of the mould between the injection of the first and second material. As well as ensuring components are perfectly positioned to receive the second shot, this higher precision results in a far shorter cycle time compared to earlier multi-component moulding concepts.

In order to ensure the rotation speed perfectly matches the processing speed of the IntElect series, POLAR-FORM Werkzeugbau GmbH fits its fast and reliable turntable inside the IntElect 130 cell. Modified to include Sumitomo (SHI) Demag’s own drive technology, it achieves a 180° tool rotation in 0.9 seconds. For this exhibit the total production cycle time is reduced to a very efficient 30 seconds.

This year’s IntElect 130 Multi machine package also showcases how valuable automation is to increase efficiency. For this exhibit, a flexible 6-axis articulated arm robot from automation partner Sepro is used to carefully extract the components after back injection, ensuring the galvanisable glossy plastic layer remains flawless in preparation for electroplating.

Drawing upon each partners’ collective strengths underpins the sustainability of 2K moulding, ensuring adhesion performance and durability of high-quality components is of the highest standard, assures Aliyev. Depending on the mould size and cavity numbers, the IntElect Multi 130 can produce four high-end vehicle interior parts in just over a minute.

Advances in LSR

Testament to the rapid growth in LSR innovations, three exhibits will also showcase how the technological advancements are aligning to the latest regulatory policies. Live demonstrations range from the manufacturing of an infusion valve on the main booth in collaboration with ACH Solution, to dental covers on the KRACHT stand (A6-6206) in cooperation with EMDE MouldTec, plus a single-cavity drip-guard in partnership with ELMET Elastomere and Momentive Performance Materials (A4-4307).

Each of these exhibits will highlight Sumitomo (SHI) Demag’s exemplary positioning in the LSR market. In particular, the company’s OPC-UA programming capabilities and how the ability to view data from integrated technology, including dosing systems, multi-cavity tooling and automation, can optimise efficiency for processors.

Infused with precision

Austrian company ACH Solution pairs up with Sumitomo (SHI) Demag on the main booth to demonstrate its unwavering diligence, precise control and stable manufacturing processes. The turnkey cell, which incorporates an IntElect LSR machine, with a dosing system, ACH cold runner and valve gate technology and ACH SERVOSHOT® 2G, delivers optimised part quality and perfect functionality.

Equipped with a 64-cavity slide mould, the system repeatably mass-produces precision infusion valves with a part weight of 0.36 grams every 22 seconds, requiring the highest processing stability. The electrically adjustable valve gate system – ACH SERVOSHOT® 2G – demonstrates how feasible it is to set up each cavity and nozzle independently. A needle stroke accuracy of 2μm, combined with regulated material flow and optional sensor-monitored filling on each cavity are just several of the ACH benefits that ensure consistently high component quality and minimal material waste.

In another healthcare LSR demonstration, visitors to the KRACHT booth (A6-6206), will have the opportunity to view the manufacturing of surgical dental protection covers on another compact, modular LSR turnkey cell. Requiring the combination of micro-thin walls and thicker beaded geometries, EMDE MouldTec supplies the gated 4-cavity mould tool, which fits into the generous tool space of the IntElect 75/420-65.

New innovative dosing solutions

A special LSR metering system from KRACHT – the Silcostar eDrive 200 Pro – sets a new standard for efficiency and equipment longevity. Designed to handle variable mixing ratios, KRACHT claims that this extends the systems’ service life by more than 10 times that of dosing systems featuring conventional ball screw drives.

Medical-ready and designed for cleanroom applications, metering data is directly connected to the IntElect processing data and the KRACHT Euromap 82.3 interface via OPC-UA, ensuring a fully traceable and stable production process. Remote access is also feasible.

Each dental article weighs just 0.425 grams, with an LSR shot weight of just 1.7 grams. Manufacturing four burr-free dental components every 25 seconds, a Sumitomo (SHI) Demag SAM-C5 robot performs the demoulding task. A special end-of-arm tool uses compressed air to delicately extract and place the dental covers into containers to comply with hygiene standards.

Smart Silicone Solutions

Demonstrating the flexibility of the LSR process, the company’s final exhibit switches focus to kitchenware. At the Momentive Performance Materials stand (A4-4307), in collaboration with ELMET Elastomere, which supplies the dosing system and mould, visitors can observe how a low-viscosity, highly reactive material like Silophen™ LSR 2760, a general-purpose two-component material, is handled and cures rapidly in a real production environment using just one LSR dosing system.

Manufacturing a drip-guard with a single shot weight of 55 grams on a single cavity tool, discover how this versatile family of elastomers, with its high thermal stability, can be applied to a range of product applications ranging from consumer goods to healthcare, automotive, LED lights and more.

“The range of applications demanding skills in LSR processing is continuing to rise, with electronics, healthcare, automotive and consumer segments driving significant growth opportunities within the market. Requiring very specialist equipment, through these partner collaborations Sumitomo (SHI) Demag has firmly positioned itself as a global leader for delivering some of the most efficient LSR injection units,” adds Aliyev.